Life assessment methods for industrial steam turbine blade to disc interfaces

- Investigators

- Katherine Soady

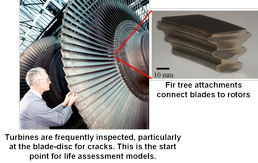

Crack initiation in steam and gas turbine blade and disc roots can lead to structural failure resulting in loss of revenue for the operator. Validated life assessment models will enable understanding of defect tolerance and crack growth, enabling the scheduling of maintenance work, to prevent such severe outages.

Shot peening is a process used to improve the low cycle fatigue resistance of such regions. The resulting residual stresses and strain hardening can be characterised by using a combination of x-ray diffraction (XRD) and electron backscattered diffraction (EBSD) Materials characterisation and mechanical testing of fatigue properties will be used to characterise the behaviour of shot peened turbine materials. Computational modelling, including the use of finite element analysis, will allow the generation of validated life assessment models using appropriate constitutive models which have been calibrated against experimental material data and which include residual stress and strain hardening effects. Research work will encompass both as-designed and repaired blade to disc geometries and will allow for simulations of life-time scatter.

Categories

Physical Systems and Engineering simulation: Elasticity, Materials, Metals, Tribology

Algorithms and computational methods: Finite elements

Visualisation and data handling methods: Surface imaging

Simulation software: Abaqus

Visualisation and data handling software: ImageJ/Fiji

Programming languages and libraries: Fortran, Matlab, Python

Computational platforms: Iridis